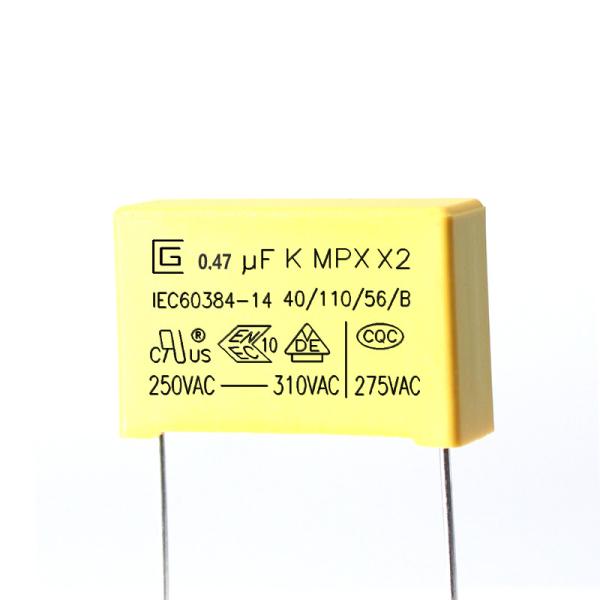

Dongguan Chenglue Electronics Co., Ltd. Number of employees: 152 employees. The company mainly produces

and sells: X2 safety capacitors, CBB21/22, metallized film

capacitors, Y1/Y2 safety capacitors, varistors. The price is 6%-8%

lower than that of peer factories. CBB21/2 capacitors, film

suppliers Qingdao Chengwen, Zhongshan Dongli, Quanzhou Jiadeli, all

products are sprayed with tin-zinc 4/6 alloy, the products used are

stable in operation under high temperature and high pressure

conditions of 105 degrees, low loss and long service life.

Conventional products are equipped with 50K-100KPCS safety stock,

large-volume conventional capacitors, and the delivery time is 3-5

days for batch delivery. Chenglue factory has a production scale of

20 Dewei winding machines, and the daily production of film

capacitors is 300-500KPCS.

Products are widely used in LED power supply, power adapter,

switching power supply, home appliance control board, lighting

appliances, automotive electronics, chargers, motors, igniters and

other electronic products. The product X2/Y safety capacitors have

passed the United States (UL), Germany ( VDE), China (CQC), South

Korea (KC) and other countries and regions product safety

certification, product environmental protection has passed the

requirements of ROHS, RECAH, halogen-free and other directives.

Since the establishment of the company, relying on advanced

production equipment, continuous improvement of enterprise

management mode, scientific and technological talents and

well-trained workforce, we have strived to make Chenglue

Electronics a supplier of electronic components for internationally

renowned brands and well-known manufacturers. The company sincerely

develops the market with the concept of "seeking reputation with

quality, seeking development with reputation, and creating value

for customers", and serves customers with the service concept of

"customer needs are our work goals"

Company advantage

Complete testing equipment and production line

At present, it has passed the in-depth inspection of SGS

institutions, ISO9001: 2015 environmental management system, and

other quality management system certifications

To provide customers with professional customized services,

according to different requirements of customers to develop,

design, produce products that meet various special needs.

Professional application engineers, door-to-door assistance in

model selection, and free technical support for customers. Provide

customers with professional customized services ,According to the

different requirements of customers, we develop, design and produce

products that meet various special needs. Professional application

engineers come to assist in model selection and provide technical

support for customers free of charge. Provide customers with

professional customized services and develop products according to

different requirements of customers. , design, and produce products

that meet various special needs. Professional application

engineers, on-site assistance in model selection, free technical

support for customers, professional customized services for

customers, research and development, design, and production that

meet various requirements according to different requirements of

customers. Professional application engineers for products with

special needs, door-to-door assistance in model selection, and free

technical support for customers. Provide customers with

professional customization services, develop, design, and produce

products that meet various special needs according to different

requirements of customers. Professional application Engineers,

door-to-door assistance in model selection, and free technical

support for customers. Provide customers with professional

customization services, develop, design, and produce products that

meet various special needs according to different requirements of

customers. Professional application engineers, door-to-door

assistance in model selection, Provide technical support to

customers free of charge

Our product range:

X2 Safety Capacitor

Y1 Safety Capacitor

Y2 Safety Capacitor

Metallized Polypropylene Film Capacitor

Super Capacitor

Metallized Polyester Film Capacitor

MMKP82 Capacitor

Aluminum Electrolytic Capacitor

Metal Oxide Varistor

SMD MOV Varistor

NTC Thermal Resistor

NTC Temperature Sensor

Hall Effect Current Sensor

Electric Vehicle Fuse

Gas Discharge Tube